Fabrication

JOB DESCRIPTION:

Fabricate extruded aluminum profiles per specified prints.

RESPONSIBILITIES:

- Follow Proper Print Specifications and Packing Instructions by Part

- Inspect Material for Scratches, Dents and Twists

- Count Parts and Verify information on Routing Tags

- Log Information into the Reporting System

- Operate Forklift for Moving and Stacking Bundles

- Verify Dimensions per Print on Aluminum Extrusions

- Report to the Fabrication Manager and Lead Person and Follow their Instructions

- Follow all Safety Procedures Including the Wearing of Required Personal Protection Equipment

REQUIRED QUALIFICATIONS:

- Ability to Stand for 8 Hours and Bend at the Waist

- Ability to Lift Up to 50 pounds

- Basic Computer and Math Skills

- Ability to Read Micrometers, Calipers, Tape Measures and Use Small Hand Tools

- Ability to Demonstrate Excellent Attendance

- Ability to Read and Follow Instructions

ADDITIONAL DESIRED QUALIFICATIONS:

These are not required, but preference will be given to those candidates who have previously had:

- Forklift Training

- Safety Training

- Environmental Health and Safety Training

Packing

JOB DESCRIPTION:

Pack extruded aluminum profiles per specified packing instructions.

RESPONSIBILITIES:

- Ensure Proper Packing Materials are Used and Parts are Securely Bundled

- Inspect Material for Scratches, Dents and Twists

- Count Parts and Verify All Information on Routing Tags

- Log Information from Routing Tags

- Verify Critical Dimensions per Print on Aluminum Extrusions

- Operate Forklift

- Report to the Fabrication Manager and the Lead Person and Follow their Instructions

- Follow all Safety Procedures

- Wear Required Personal Protection Equipment

REQUIRED QUALIFICATIONS:

- Ability to Stand for 8 Hours and Bend at the Waist

- Ability to Lift Up to 50 pounds

- Basic Computer and Math Skills

- Ability to Read Micrometers, Calipers, Tape Measures and Use Small Hand Tools

- Ability to Demonstrate Excellent Attendance

- Ability to Read and Follow Instructions

ADDITIONAL DESIRED QUALIFICATIONS:

These are not required, but preference will be given to those candidates who have previously had:

- Forklift Training

- Safety Training

- Environmental Health and Safety Training

Thermobreak Setup/Operator

DEPARTMENT DESCRIPTION:

Debridging separates the metal from under the cavity, to prepare for Thermobreak. Thermobreak puts thermal glue into various cavities (where glass will be placed).

MAIN RESPONSIBILITIES:

Set Up: Set up equipment, getting the metal prepared for runs, make sure the ratio checks on the fill machine and the hardness test on the debridger are within the qualified dimensions. Check metal for dimensions.

Thermofill: Run metal through, does dimension checks

Debridger: Metal moves from fill machine on the conveyer belt, employee picks up part moves to debridger machine, pick up and move to chop saw table, use saw to cut small sample piece, test sample piece move over to conveyer belt to send to packing.

Packers: Pack metal, close bundles, make up tickets. Foam interweave or a paper layer. Some companies ask for metal banding, others use green plastic banding.

PHYSICAL REQUIREMENTS:

- Bending

- Lifting up to 50 pounds up to waist

- Pulling racks in and out of area with use of electric dolly

- Ability to stand for long periods of time.

DESIRED SKILLS:

These are not required, but preference will be given to those candidates who have previously had:

- Read calipers

- Ability to read a tape measure

- Be able to read prints for dimensions

- Basic math

Die Setter

POSITION SUMMARY:

Our manufacturing plant is seeking a dependable and precise Die Setter. In this role, you will set up presses that range in size and choose the appropriate fixtures for each job. All items will be completed accurately and consistently; may conduct quality assurance tests using precision measuring tools. All applicants must be able to pass a pre-employment drug screening.

ESSENTIAL FUNCTIONS:

- Perform duties in a safe manner and follow all safety procedures.

- Set presses and fixtures.

- Clean dies daily.

- Use precision measuring tools such as micrometers and calipers to ensure products are made to specification.

- Troubleshoot issues with equipment.

- Assist operators as needed.

- Maintain clean and safe workspace.

REQUIREMENTS:

- Attention to detail and familiarity with industrial equipment.

- High School Diploma/GED preferred.

- Basic math, reading and record keeping skills required.

- Ability to lift 50 pounds unassisted and up to 75 pounds as a team lift.

- Ability to follow written and verbal instructions.

- Other duties as assigned by Supervisor.

WORKING CONDITIONS:

- Work involves standing, walking, reaching, using a keyboard, stooping, kneeling, repetitive motion and moving, lifting or pushing objects weighing up to 100 pounds.

- Plant environment may be hot, floors may be slippery and uneven.

- May be exposed to a wide range of temperatures.

- Noise level may be moderate to loud.

Saw Helper

DESCRIPTION:

Assists Saw Operator to cut and finish material to required lengths

PRIMARY RESPONSIBILITIES:

- Check surface for discoloration, scratches, and other surface defects while handling the extruded product.

- Place scraped pieces in scrap containers.

- Cut extrusions and assist with the transfer of extrusions.

- Rack metal for heat treatment.

- Operate forklift to empty scrap hoppers, record weight and level scrap trailers.

- Check metal on beam for twist and bow, empty scrap hoppers and record weights and empty garbage hoppers.

- Keep work area clean in accordance with cleanliness and safety standards.

- Assist Saw Operator in transferring metal over to the saw conveyor.

- Check control dimension with gauges and calipers.

- Read and follow prints.

- Assist Saw Operator in his duties to include but not limited to: setting up stop, making rack tickets.

- Follow instruction from Manager, Team Lead, Stretcher Operator and Saw Operator.

- Use correct hand signals to communicate with stretcher operator, extrusion press operator, and saw operator.

- Wear all required PPE (Personal Protective Equipment) at all times. Safety glasses, steel toe shoes, ear plugs/muffs, gloves, and apron if needed.

- Correctly read digital/mechanical calipers and micrometers.

- Act as a quality check and inform Manager, Team Lead, and Saw Operator if non-conforming extrusions (scratches, die lines, incomplete stretches, etc.) are detected.

- Record Go/No Go gauge readings

- Transfer product to temper ovens.

- Perform “Checks” during stretching process to ensure extrusions have quality form and finish.

- Inspect forklift (PIT- Powered Industrial Truck) at the beginning of each shift for mechanical defects and safety concerns.

COMPETENCIES REQUIRED:

- Be able to stand for a minimum of 8 hours.

- Be able to bend easily at the waist.

- Be able to lift up to 50 pounds.

- Be able to read a tape measure accurately.

- Be able to read work instructions.

- Be able to demonstrate basic math skills.

- Must have basic computer skills.

- Be able to use small hand tools, including hammers, screw drivers, etc.

- Be able to read micrometers and calipers.

- Must have demonstrated excellent attendance and have reliable transportation

COMPETENCIES DESIRED:

- Forklift training.

- Safety training.

- Environmental Health and Safety Training.

EDUCATION REQUIREMENTS:

- Must have high school diploma or GED.

Unracker

JOB DESCRIPTION:

Unracks painted material off paint line. Inspects parts for any defects and place them on the proper packing racks. Enters info on the routing tags and into the computer.

Inspect material coming off of the paint line for any defects. Including in metal or paint related. Stack parts on carts and place tabs on thermal pocket. Verify piece counts on carts, put correct count on tag and put tag on the cart. Document all production info on production report as well as on the routing tags. Enter all production info into the computer in a timely manner. Operate forklift for stacking and moving carts. Keep work area clean and safe. Be able to read and understand info on routing tags. Follow instructions from Paint Manager and Lead Person. Wear all required PPE. Check the dry paint film thickness for each profile being painted. Check drawings in the computer for proper packing procedures. Must be able to stand for a minimum of 8 hours. Must be able to bend easily at the waist. Must be able to lift up to 50 pounds. Must be able to read a tape measure accurately. Must be able to read work instructions. Must be able to demonstrate basic math skills Must have basic computer skills Must be able to use small hand tools, including hammers, screw drivers, etc. Must be able to read micrometers and calipers Must have demonstrated excellent attendance Must have reliable transportation

COMPETENCIES REQUIRED:

- Be able to stand for a minimum of 8 hours

- Be able to bend easily at the waist

- Be able to lift up to 50 pounds

- Be able to work in a non-controlled climate facility

- Have excellent attendance (Strong Work Ethic)

Racker

JOB DESCRIPTION:

Inspects and hangs material on racks to be painted.

RESPONSIBILITIES:

- Inspect Material for any Scratches, Dents and Twists

- Load and Clean Racks

- Ensure the Proper Rack is Used and the Parts are Secured Properly

- Count Parts and verify all Information on Routing Tags

- Log Information from Routing Tags

- Report to the Paint Manager and Lead Person and Follow their Instructions

- Operate Forklift

- Keep the area Clean

- Follow all Safety Procedures

- Wear Required Personal Protection Equipment

REQUIRED QUALIFICATIONS:

- Ability to Stand for 8 Hours and Bend at the Waist

- Ability to Lift Up to 50 pounds

- Basic Computer and Math Skills

- Ability to Read Micrometers, Calipers, Tape Measures and Use Small Hand Tools

- Ability to Demonstrate Excellent Attendance

- Ability to Read and Follow Instructions

ADDITIONAL DESIRED QUALIFICATIONS:

These are not required, but preference will be given to those candidates who have previously had:

- Forklift Training

- Safety Training

- Environmental Health and Safety Training

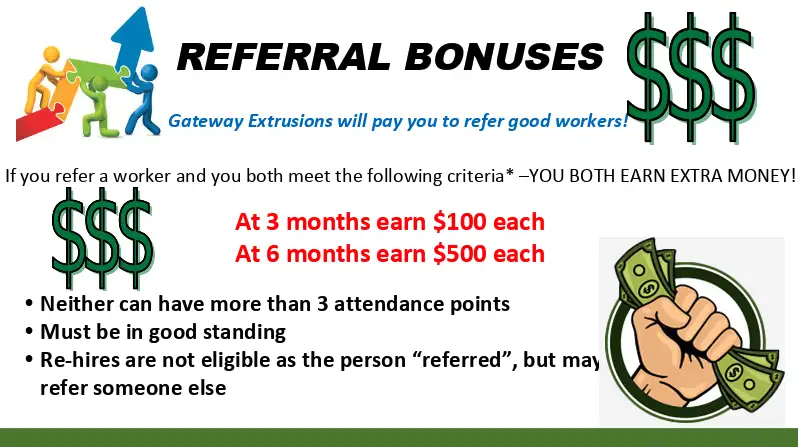

Gateway Extrusions offers a competitive salary and a safe working environment. Benefits include Medical/Dental/Life/Vision/Short-Term disability and 401(k) Extra Incentives including referral bonuses, quarterly bonuses, and perfect attendance awards.

Application