Gateway Extrusions News

Gateway Extrusions Marks Major Expansion & 15th Year

National Aluminum Fabricator Celebrates Anniversary with Open House

UNION, MO, October 5, 2018 – National aluminum fabrication firm Gateway Extrusions, headquartered in Union, MO, hosted an open house on September 28, 2018 to mark its recent $15 million expansion and its 15th year of growth and success since opening in 2003. Customers, vendors, members of the local business community, and government officials joined Gateway’s management team for tours of the facility, demonstrations of its new equipment, and a networking luncheon.

Gateway Extrusions, national aluminum extrusion and finishing company headquartered in Union, MO, hosted an open house on September 28, 2018 to mark its recent $15 million expansion and 15th year of operations and growth. Shown (l. to r.) are Gateway’s facility, ceremonial ribbon- cutting, and factory tour group at Gateway’s 9-inch aluminum extrusion press.

Tom Ziegler, President of Operations, gave a presentation on the history of Gateway’s growth, its sizable investments in property and equipment in Union, and the company’s plans and opportunities for further growth.

“The aluminum extrusion manufacturing industry is growing in Union,” said Ziegler. “Gateway’s investment of $15 million in new equipment and additional property and buildings means we are here to stay with plenty of room to grow in the future. Union is a terrific location to grow for many reasons. The labor force, the supportive business community, proximity to markets in every direction, the cost of operations, and the quality of life have made this the perfect choice for Gateway.”

Union City Mayor Mike Livengood shared with the audience his observations of Gateway’s success over the years, praising the company’s expansion and investments, and noting the company is a great employer and a committed, financially sound business for the community. Then Mayor Livengood, other city officials, and representatives for U.S. Senator Roy Blunt and Missouri’s Department of Economic Development joined Gateway executives in a ceremonial ribbon-cutting to open the expanded factory, signifying Gateway’s future.

Gateway has had a major impact on the regional economy as well as the City of Union. “More than half of our vendors are based in Missouri, supplying materials, goods, and services required to keep our aluminum extrusion operations running smoothly,” said Ziegler. “We have doubled our workforce to over 130 employees since 2014 with the addition of new equipment and services. We have added new customers, many of which are right here in the region, and our annual production has doubled since 2015.”

Gateway opened in 2003 with the acquisition of the existing shuttered Cupples Aluminum Products plant in the Union Industrial Park by Gateway’s parent company, national manufacturer Crystal Window & Door Systems, headquartered in New York. Gateway was launched to vertically integrate Crystal’s manufacturing and control quality and was soon supplying nearly all the parent company’s aluminum profile needs.

As it grew, Gateway’s sales moved beyond the parent company into many other markets, requiring the company in 2014 to enter a multi-year production expansion program. Major renovations and additions to the existing factory were completed. New 7-inch and 9-inch aluminum extrusion presses were acquired, significantly increasing capacity, efficiency, and capability. A new environmentally sustainable vertical powder coat paint line was added, doubling Gateway’s throughput of finished profiles. Now more than half of Gateway’s annual production is for customers other than its parent company.

“Our customers and employees can look forward to further improvements to our facility, such as a new administrative office addition, enhancements to the exterior parking and landscaped areas, and renovations to the adjacent 200,000 sq. ft. buildings Gateway purchased,” said Ziegler. Currently these buildings are rented and fully occupied by another local manufacturing firm, keeping this industrial property economically viable. Long-term, Gateway may explore opportunities to add new production processes in Union, related to its parent company’s fenestration manufacturing operations.

Gateway’s open house preceded National Manufacturing Day on October 5, an annual event sponsored by the National Association of Manufacturers and the Manufacturing Institute to highlight modern manufacturing’s economic, career, and national strategic significance. “Manufacturing is alive and well at Gateway, and we look forward to a long, successful time here in Union,” said Ziegler.

Gateway Extrusions Expands Workforce

Aluminum Extruder Doubles Jobs With Recent Expansion

UNION, MO, February 21, 2018 – Gateway Extrusions, a leading national aluminum extrusion and finishing firm, is pleased to announce significant job creation at its Union, MO, facility. With the recent expansion of its manufacturing facility, the addition of new production equipment, and growth in sales, Gateway has seen a 100% increase in staffing since late 2014. Currently, employment stands at 130 and the company is seeking additional workers from the area as the new equipment is ramped up to full production.

“I’m extremely happy that Gateway has been able to double its workforce in just a few short years,” said Thomas Ziegler, President of Operations for Gateway Extrusions. “I’m also proud that Gateway is now one of the largest employers in the area. The City of Union has been very supportive of Gateway and job creation is the best way I know that a company can contribute to the local community.”

Ziegler further adds, “As sales increase and our brand new state-of-the-art equipment comes into full production, we will require even more workers. Therefore, we continue to seek good qualified employees to join our vibrant, growing company.”

To ensure the company’s employees are well prepared to meet customer and company needs, Gateway has implemented several initiatives in addition to ongoing skills training, such as employee recognition activities and a mentor program for new employees. “We match new employees with a ‘Big Brother’ or ‘Big Sister’ here, an experienced senior staff member who will take an interest in the new employee’s development, ask them how the job is going, offer advice, etc.,” said Ziegler. “It helps new employees come up to speed quickly and makes them feel part of the Gateway team.”

Download the News Release:

Gateway Extrusions Installs New Vertical Paint Line

Aluminum Extruder Expands Capabilities with State-of-the Art Finishing Equipment

UNION, MO May 15, 2017 – National aluminum extruder Gateway Extrusions recently invested in a new vertical powder coat paint finishing line, which is now installed, tested and in full operation. The new system enables Gateway to process longer profiles more efficiently and faster than its previous horizontal paint line and enables the company to serve a broader array of markets.

“Many customers need the longer profile lengths and with this state-of-the-art powder coating line, we can deliver faster and with greater quality the finished extrusion products our customers want and need,” said Tom Ziegler, President of Operations for Gateway Extrusions. “The new vertical paint line allows Gateway to handle lineals up to 25 feet, compared with 18 feet with our old equipment.”

The new vertical powder coat paint system offers many advantages. It provides more efficient application of powder, with greater consistent overall coverage and minimal waste. Gateway has increased throughput two to three times over its previous horizontal paint line, running one shift with 10 employees, compared to two shifts with 16 employees on the old line. This has significantly improved productivity and enabled Gateway to reassign employees to other areas where they are needed. The system also allows rapid color changes to minimize downtime and overspray. Following paint application, extrusions pass through a two-stage drying oven, where the metal pieces are warmed in an infrared oven before entering the bake oven. This results in a harder finish than a single-stage bake oven.

Gateway’s new paint equipment, acquired after extensive research, represents a collaboration between several notable suppliers to provide the entire system. “We were very impressed with the innovation, engineering, and customization our suppliers brought to this project,” said Ziegler. “They worked together very effectively to bring our new equipment online, on budget and ahead of schedule.”

Bulk Chemicals of Reading, PA designed the chrome-free pre-treatment wash system to minimize chemical usage and maximize the effectiveness of cleaning and preparing the surface of the aluminum profiles to accept the powder paint. The supplier customized its pre-treatment solutions to work very effectively with the new paint line’s waterfall application system.

International manufacturer Gema of Switzerland supplied the powder applicationequipment,considered the industry’s most advanced, including the vertical track spray gun array and automation software to control paint application. The Gema guns use an electro-magnetic field to sense the aluminum profiles in order to charge the powder paint in real-time, ensuring a highly effective and optional finishing application.

Gema spray application equipment.

Both Sherwin Williams and PPG supply the powder paint, formulated specifically for the new equipment. All Gateway extrusions are finished to meet AAMA 2604 durability performance criteria, and the higher performance standard of AAMA 2605 is also available with the new paint line.

Gateway’s paint line is designed with environmental sensitivity as well as Gateway Extrusions’ new paint line effectiveness. The powder reclamation system is engineered for high features Gema spray application efficiency. The powder coating booths are equipped with rolling curtains equipment. and engineered vacuum chambers that ensure maximum powder re- utilization, with minimal waste. The paint line also features a state-of-the-art real-time water management system to manage pH levels, outflow rate, and temperature to ensure all local environmental requirements are continuously met.

Installation of the new equipment required the construction of a new 50-ft. high building addition to Gateway’s existing facility to accommodate the vertical components of the system. Removal of the old paint line equipment and creation of a new shipping area in the front of the factory allows a more efficient flow of materials and products through the building. The overall investment in new plant and equipment was several million dollars.

The new vertical paint line is part of a multi-phase expansion plan for Gateway. In 2015, Gateway purchased its 129,000-ft2 production plant that it had been leasing in the Union Industrial Park, as well as adjacent properties. The company also purchased a new 7-inch extrusion press to upgrade existing equipment. The following year, Gateway expanded capabilities with the purchase and installation of a second press to accommodate 9-inch extrusions. Future plans include construction of new office space, additional exterior driveways, paved parking areas, and new landscaping.

Gateway Extrusions Names New President

Aluminum Extruder’s Vice President Promoted to Lead Company

UNION, MO, January 23, 2017 – Gateway Extrusions is pleased to announce that Thomas Ziegler has been named the company’s new President. Ziegler has over 30 years of experience in the aluminum extrusion and fabrication industry and has been with Gateway Extrusions for 11 years. Coming on board in 2006, Ziegler previously held the titles of General Manager and Vice President. He has directed progressive company expansions, added experienced managers and employees, and he has been instrumental in developing new markets for the company’s extrusion and finishing services.

“I am proud to be part of Gateway Extrusions, and now to lead it into the future,” said Ziegler. “Through hard work and perseverance, the company has grown steadily from start up in 2003. Initially, we had a limited product line serving a small customer base, and now we provide a wide variety of extrusions to customers throughout the country. Our current expansion and growth activities are positioning Gateway to be a national leader in the industry, with the capacity, services and quality our customers have come to expect.”

Starting in 2015, Ziegler has been responsible for leading another significant multi-year phased expansion of the company. Gateway acquired its existing building which it had been leasing and bought the adjacent property for possible future expansion. The company invested in a new 7-inch aluminum extrusion press and renovated the building to accommodate a new 9-inch aluminum extrusion press recently installed, as well as a new vertical powder coat paint line that will be operational soon.

Prior to joining Gateway Extrusions, Mr. Ziegler held positions of progressively greater responsibility at Alcoa; most recently he was Operations Manager for Alcoa’s 500,000 square foot extrusion manufacturing facility in Georgia. There he directed the production of 50 million pounds of aluminum building and construction products annually, increasing employee involvement and improving safety. Also while with Alcoa, he led the conversion of an existing Mississippi aluminum extrusion plant into an architectural storefront systems manufacturing facility.

Download the News Release:

Gateway Adds Second New Press

Aluminum Extruder Increases Services and Efficiency With New Press

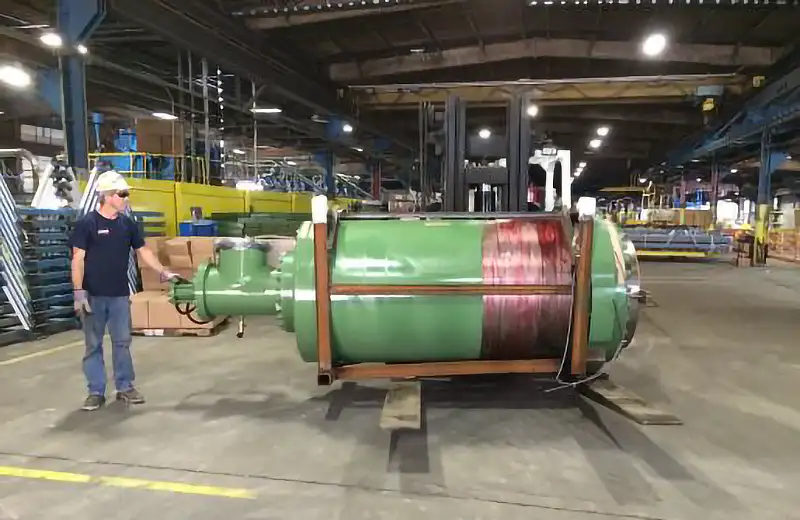

UNION, MO, December 9, 2016 – National aluminum extruder Gateway Extrusions continues its multi-phase expansion program with the acquisition of a new 9-inch aluminum extrusion press. Purchased this summer and installed this fall, the equipment is in final stages of testing and calibration before being brought into full operation. The new press complements a new 7-inch aluminum press installed a year ago.

“This state-of-the-art large press will allow Gateway to supply heavier, stronger components for curtain wall systems and heavy-commercial windows, and also to continue expansion into new markets such as automotive and other transportation components,” said Tom Ziegler, Vice President for Gateway Extrusions. “We will be able to offer our customers the extruded profiles they need in a broader range of lengths and tempering with this new 9-inch press. The system’s features allow us to operate very efficiently, moving from one extrusion order to the next with minimal transition time in between.” Once fully operational, the new 9-inch press will increase the company’s current throughput in pounds-per-hour by at least 50%.

Gateway’s new 9-inch, 2,750-ton extrusion press system includes many notable production features and benefits. The system provides for saw lengths from 8 ft. to 30 ft. with inspection tables and a 174-ft. run out capability. The high-temperature felt belt handling system keeps extrusions flawless. For extrusion orders that require it, the standing wave quench system will enable Gateway to provide harder structural alloys, such as 6061, 6105 and 6005A, in the final cooling process than the company’s currently operating 7-inch press.

While the new 9-inch press was on order from the manufacturer, Gateway completed removal of a retired extrusion press and significant renovations to the existing building to accommodate the new equipment. The existing concrete floor was demolished, and a new larger foundation and reinforced concrete floor was poured to support the new press, and existing equipment was relocated to better accommodate process flows within the building. To gain a more open floor plan, structural support columns were moved, and the roof reinforced. “We are planning and staging the work to continue operations throughout the renovations and avoid service interruptions for our customers,” said Ziegler.

Production speed and efficiency are also improved. A dual pocket die slide combined with the four double cell infrared die ovens facilitate quick change outs and minimize down time between runs. The system’s 75-ton automated final stretcher can be operated by one worker, instead of the two commonly required.

Gateway is currently recruiting experienced supervisors and additional crew members needed to operate the new 9-inch press and orientation and training will follow. The company is also acquiring dies and tooling to provide a broad array of extruded profiles for customers. Production is slated to begin early in 2017 and to ramp up quickly thereafter.

The new 9-inch aluminum press purchase is part of Gateway’s multi-phase expansion program, which includes upgrading existing equipment, adding new equipment to increase capacity, and constructing additions to the factory and office spaces to accommodate new services. Last year, the company purchased its current 129,000- ft2 facility, which it had been leasing, as well as the adjacent 200,000-ft2 (4.6 acre) property in the Union, MO industrial business park. Construction of an addition to house a new vertical paint line is nearing completion, and the new paint equipment is expected to be installed in the coming months.

Download the News Release:

Gateway Extrusions Adds New Equipment

Aluminum Extruder Increases Services and Efficiency With New Press

UNION, MO. December 11, 2015 – Fast growing national aluminum extruder Gateway Extrusions has implemented the second phase of its multi-phase expansion program with the acquisition of a new 7-inch extrusion press. Purchased and installed this summer, the equipment underwent rigorous testing and calibration before being brought into full operation this fall. The new press represents a major upgrade from the company’s existing 7-inch aluminum press.

“This state-of-the-art press has greatly enhanced our capabilities and improved production speeds,” said Tom Ziegler, Vice President for Gateway Extrusions. “We’re able to offer our customers the extruded profiles they need in a broader range of lengths and tempering with the new equipment. The system’s features allow us to operate more efficiently, moving from one extrusion order to the next with minimal transition time in between.” The company is already seeing significant increases in the new unit’s net pounds per hour throughput and will build on that with additional operations improvements.

Features of Gateway Extrusions’ new 7-inch extrusion press system includes single cell die ovens, misting quench hoods and finish saw and inspection table, which provide greater product capabilities, faster turnaround times, and more efficient operations.

Gateway’s new 7-inch, 1,880-ton extrusion press system includes many notable production features and benefits. The system provides saw lengths from 4 ft. to 30 ft. with inspection tables and a 148-ft. run out capability. The high-temperature felt belt handling system keeps extrusions flawless. For extrusion orders that require it, the misting quench hoods produce harder metal in the final cooling process than air cooling.

Production speed and efficiency are also improved. A dual die changer coupled with the six single-cell infrared die ovens facilitate quick change outs and minimizes down time between runs. The system’s 40-ton automated final stretcher reduces the number of required operators by 50%.

“Delivery and installation of the new equipment were expedited by the extra steps taken by the equipment manufacturer to fully assemble and test the entire press line at its factory before breaking it down again into modules for shipment,” said Ziegler. “Once the equipment arrived, the team re-assembled the modules and it was up and running in a fraction of the time we anticipated.”

The new 7-inch aluminum press purchase is one part of Gateway’s multi-phase expansion program, which includes upgrading existing equipment, adding new equipment to increase capacity, and constructing additions to the factory and office spaces to accommodate new services. Earlier this year, the company purchased its current 129,000-ft2 facility, which it had been leasing, as well as the adjacent 200,000-ft2 (4.6 acre) property in the Union, MO industrial business park. Construction plans are underway for 2016 to add to the existing facility to house further equipment acquisitions.

Download the News Release:

Gateway Extrusions Launches Expansion to Meet Growth

Aluminum Extruder Adding Space, Equipment and Capacity

UNION, MO, June 8, 2015 – Gateway Extrusions, a fast-growing extruder of small diameter aluminum profiles, has embarked on a significant expansion of its Union, MO facility. The company recently purchased its 129,000-ft2 production plant that it had been leasing in the Union Industrial Park, as well as adjacent properties, and is nearing completion of renovations to accommodate additional equipment coming online this year.

“Gateway Extrusions has seen considerable growth in its sales and the variety of markets it serves, a result of the strategic plans put in motion over the past several years,” said Tom Ziegler, Vice President for Gateway Extrusions. “This investment and expansion of our Union, MO facility represents another step in the company’s overall growth goals.” The company moved forward with the first phases of expansion, to purchase the plant, renovate the space and acquire the first of several new major pieces of equipment, a new aluminum billet extrusion press.

Gateway Extrusions engaged two local professional firms for the construction and renovations necessary at the factory – Washington Engineering & Architecture of Washington, MO is handling the design and engineering aspects of the renovations, and general contractor Lewis & Associates of Union, MO is the on-site construction manager.

“The City of Union has been extremely supportive and has worked closely with us to ensure our permits and applications meet all requirements,” said Ziegler. “Fellow Union business owners and the community are also excited about the expansion. They know this investment signals our continued commitment to being a major employer in Union for the long term.”

Construction is expected to begin later this year on a new 19,000-ft2 addition to the building to house a new vertical powder coating paint line, part of Gateway’s next phase of investment and expansion.

Gateway Extrusions serves customers across the country in fields such as lighting, shelving and storage systems, partitions, solar racking systems, railings and fencing, and boat and trailer accessories, as well as window and door manufacturers. In addition to extrusion and finishing, Gateway Extrusions provides custom design and value engineering services to bring customer concepts cost-effectively into production.